Old Electrical Equipment - GEC Metal Fusebox

An old General Electric Company metal fusebox with three fuseways.

Exterior - Front

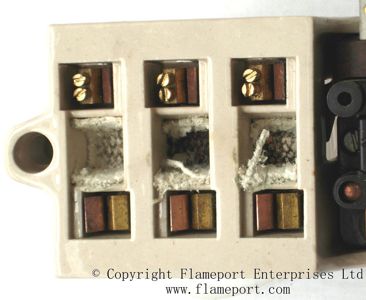

The outer case is metal, probably steel with a paint finish. The front cover is secured with a single fixing, which is designed to be undone with fingers.

The outer case is metal, probably steel with a paint finish. The front cover is secured with a single fixing, which is designed to be undone with fingers.

The main switch is interlocked to the fixing, so that the cover can only be removed when the switch is in the Off position.

The front cover has the 'GEC' logo embossed into the metal. The 'Lights' label was added later by someone using a plastic-crunching Dymo labelling device.

The small yellow label warns to switch off before opening, and refers to the interlocked cover fastening.

This example is excessively dirty, and was probably installed in the 1960s.

Exterior - Back

There are three fixing holes in the back, and various knock out points for wiring to enter. As the case is metal, rubber grommets or washers are essential to prevent cables being damaged on the sharp edges.

There are three fixing holes in the back, and various knock out points for wiring to enter. As the case is metal, rubber grommets or washers are essential to prevent cables being damaged on the sharp edges.

One of the holes still has the fixing screw in it, together with the wooden wall plug still attached to the screw.

As is usual with older electrical installations, the case is daubed with white emulsion paint.

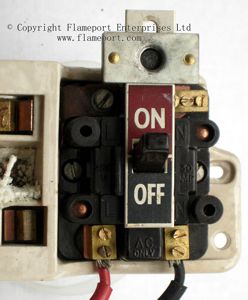

Interior - Front cover removed

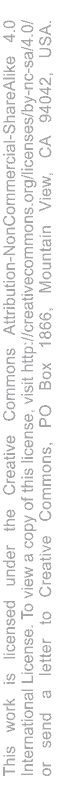

This is the view with the front cover removed. This is obtainable without tools, and is the expected method for replacing fuses.

This is the view with the front cover removed. This is obtainable without tools, and is the expected method for replacing fuses.

The switch is in the OFF position, and fuses can be removed and rewired. Note the paxolin cover over the switch terminals - cover removed in the second image.

The red and black cables originally extended through the hole in the base, but have been cut off when the box was removed from service.

Interior - Fuses removed

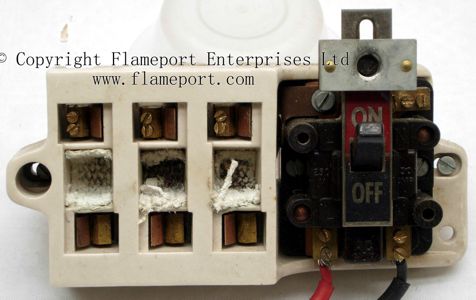

Here, two fuses have been removed. The circuit wiring connected to the top terminals, and was secured with the two small screws. The lower terminal is connected to the switch, and would be live when the switch is on.

Here, two fuses have been removed. The circuit wiring connected to the top terminals, and was secured with the two small screws. The lower terminal is connected to the switch, and would be live when the switch is on.

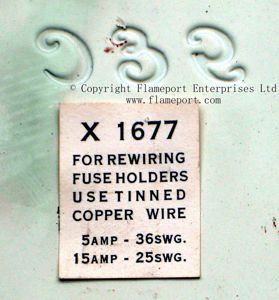

The inside of the lid has a paper label with details of the size of wire to be used - 36swg for 5 amps, 25swg for 15 amps.

Components - Vitreous Ceramic

The main component is made from a fired ceramic material to which the metal parts are attached.

The main component is made from a fired ceramic material to which the metal parts are attached.

The white pads in the centre of the terminals are probably asbestos cloth, and were intended to absorb the arc caused when a fuse fails. Two of them are significantly blackened from previous faults.

The back has a single copper strap which connects the switch terminal to the bottom three fuse contacts. Circuit wiring connected to the top terminals of each fuse, with neutrals to the terminal on the top right of the switch.

Components - Details

A closer view of the fuse contacts amd the wording on the back of the ceramic piece.

A closer view of the fuse contacts amd the wording on the back of the ceramic piece.

G.E.C. 4C 3274 VITREOUS MADE IN ENGLAND 8038

Metal Base

The ceramic piece secures to the metal base with only two screws. A paxolin sheet provides insulation between the two parts - some of the metalwork on the back of the ceramic is live.

The ceramic piece secures to the metal base with only two screws. A paxolin sheet provides insulation between the two parts - some of the metalwork on the back of the ceramic is live.

The single earth terminal can be seen at the lower left. This was for the incoming earth wire, and the earth wires from the individual circuits if they had them.

At the time this was fitted, it was common for lighting circuits to be wired without an earth.

Main Switch

The main switch has incoming terminals at the bottom, which by todays standards are very small. The wires shown are approximately 6mm csa.

The main switch has incoming terminals at the bottom, which by todays standards are very small. The wires shown are approximately 6mm csa.

The cover interlock is a very simple yet effective mechanism - the cover screw fits into the round hole above the switch. This presses a small plate to release the switch. Moving the switch to the On position slides the metal piece downwards over a slot in the cover screw, preventing it being removed.

This ensures the cover cannot be removed unless the switch is Off, and also prevent the switch being move to On without the cover in place.

Fuses

The fuses are made from the same vitreous ceramic material, and have replaceable fuse elements. The main terminals are brass.

The fuses are made from the same vitreous ceramic material, and have replaceable fuse elements. The main terminals are brass.

Both of the centre sections are burnt from where fuses have blown previously.

Additional closeup pictures

Fuses and the shield from the main switch. Only one fixing screw is shown - originally it had two, but the other is missing.

Fuses and the shield from the main switch. Only one fixing screw is shown - originally it had two, but the other is missing.

Base stamp - on the back outer of the metal box, this was presumably a production code or date. It is excessively smudged.

Label on the inside of the lid stating the size and tupe of fusewire to use.