UK 13A Plugs (BS1363 Plug) - How to Fit

Fitting a new plug is a straightforward task. Apart from the plug itself, you will need a trimming/DIY knife, wire strippers and a small flat blade screwdriver.

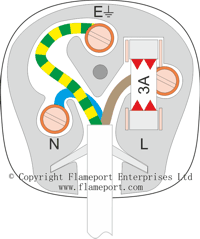

Post Terminals

- Unscrew the central screw on the back of the plug. The lid can then be removed.

- Remove the fuse. It simply clips between the metal holders.

- Unscrew and remove the three terminal clamps. Place the clamps to one side so they are not lost.

- Using the knife, cut away the outer insulation, taking care not to damage the inner wires. Place the flex against the plug and trim the inner wires so that they reach the three terminals.

- Remove about 10mm of the insulation from the end of each wire using the wire strippers.

- Twist the wire strands together, then wrap the wires clockwise around the terminal posts.

- Press the flex between the flex grip.

- Replace the three terminal clamps and tighten.

- Check. There should be no loose strands of wire, all of the exposed copper wire is under the clamps, and there is no plastic insulation under the clamps.

- Insert the fuse.

- Replace the lid and tighten the central fixing screw.

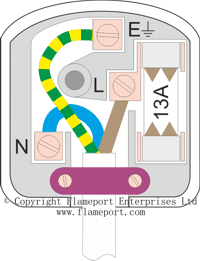

Pillar Terminals

- Unscrew the central screw on the back of the plug. The lid can then be removed.

- Loosen the two smaller screws for the flex grip bar.

- Unscrew the three small terminal screws, but do not remove them.

- Using the knife, cut away the outer insulation, taking care not to damage the inner wires. Place the flex against the plug and trim the inner wires so that they reach the three terminals.

- Remove about 5mm of the insulation from the end of each wire using the wire strippers.

- Twist the wire strands together.

- Pass the flex under the grip bar.

- Insert the wire ends into the terminals and tighten the terminal screws.

- Tighten the two screws to clamp the flex.

- Check. There should be no loose strands of wire, all of the exposed copper wire is in the terminals, and there is no plastic insulation under the terminal screws.

- Replace the lid and tighten the central fixing screw.

Further details

Before replacing the lid, always check that the wires are in the correct terminals.

When preparing the flex, the earth wire should be cut slightly longer, so that if the flex were pulled out, the live and neutral would be disconnected before the earth wire.

If replacing a damaged plug, it is a good idea to cut off the last 150mm of flex, as this is often damaged where it enters the plug.

If the wire is very thin, and you are using a plug with pillar terminals, strip off 10mm of insulation, twist the wires together and then fold the exposed wire in half. This will give a larger area for the screw to clamp against.

If the wires have solder on the ends (tinned), cut this off. Solder will creep under the pressure of the screw and result in a loose connection.